Company Details

Company Details

Warp Knitting Machine ( 34 )

Warp Knitting Machine ( 34 ) Warping Machine ( 6 )

Warping Machine ( 6 )What Raschel Jacquard Machine Can Produce

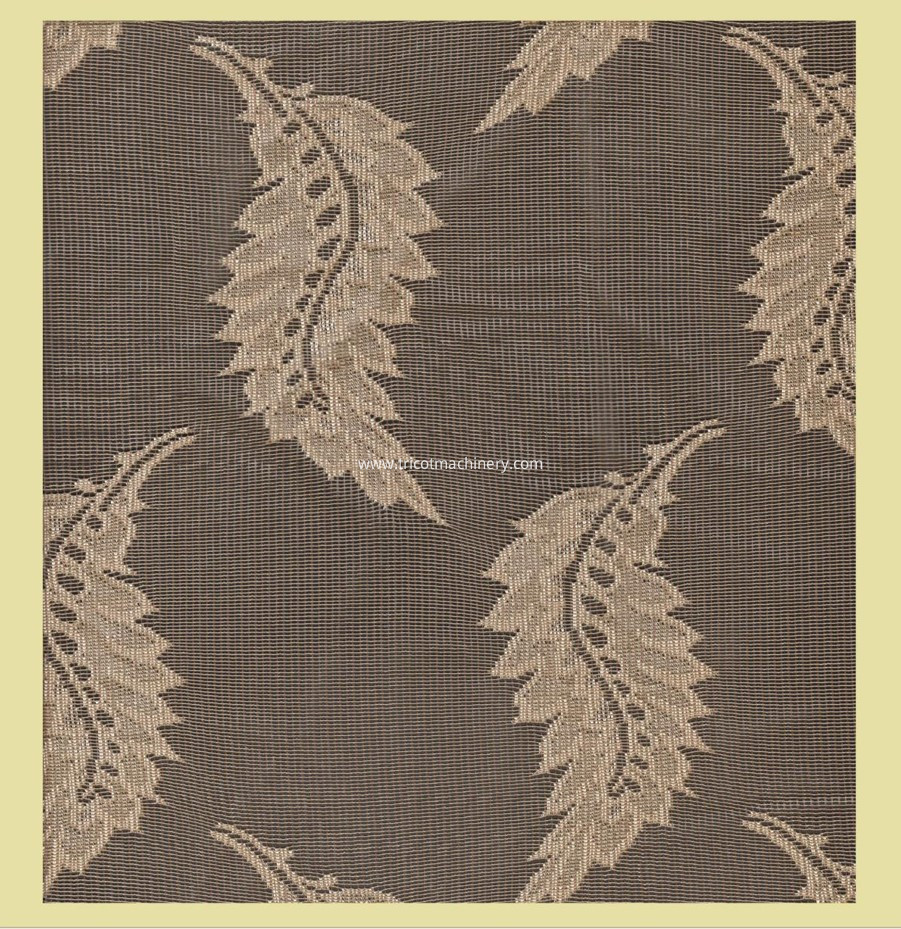

TH-4/1F is Raschel Jacquard Fall-plate Warp Knitting Machine, its textile application widely used in garments, home textiles, such as curtain, table covers, chair covers, etc.

The piezo jacquard placed front moves in shogging way only, and fall-plate moves vertically, while ground bars behind moves both shogging and front-and-back form.

The advantages of such structure of TH-4/1F lie in that piezo jacquard could make two needle overlap.

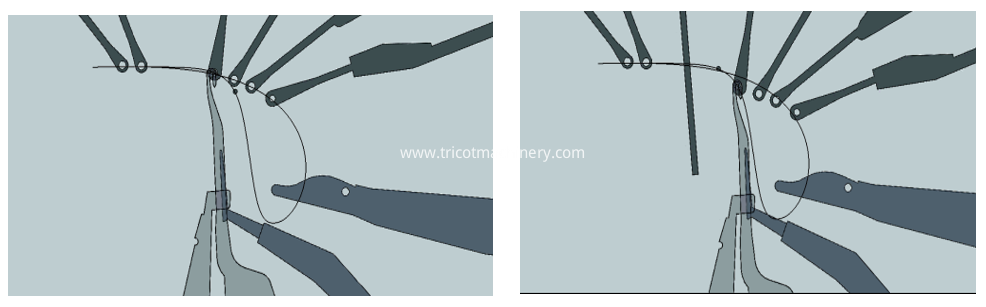

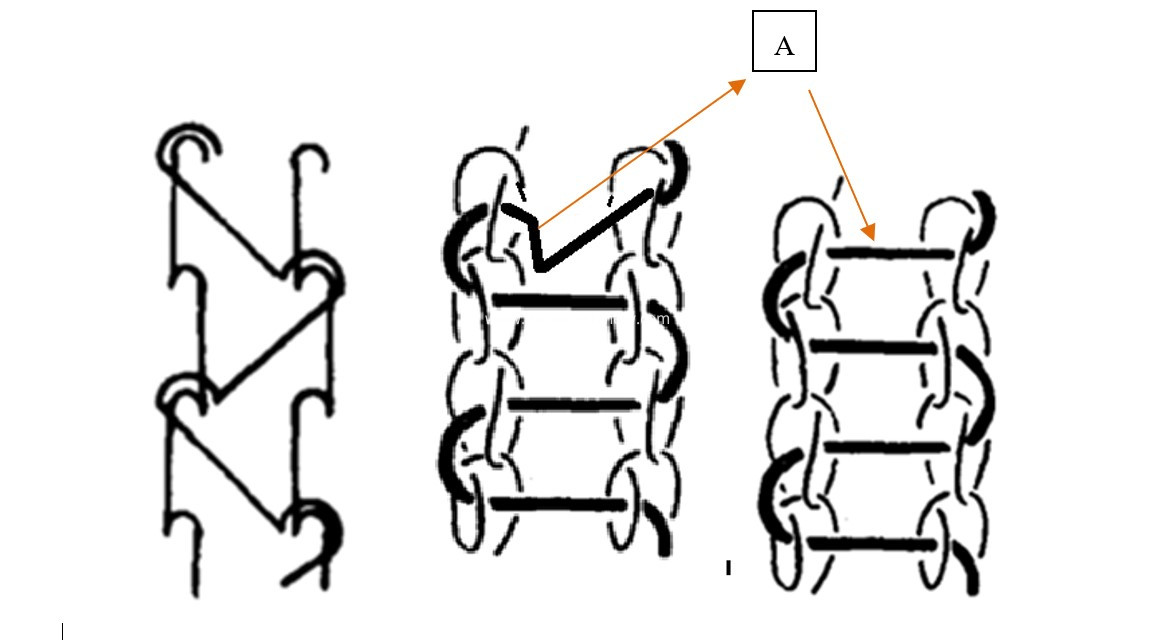

One advantage of two needle overlap is that the fall-plate effect becomes more obvious especially after dyed Yarn used on jacquard needles which makes its outstanding from ground net, see image 1.

Image 1

What`s more, piezo jacquard moves either overlap or underlap, so its lapping movement becomes more various, the longer reciprocating lapping movements is possibly.

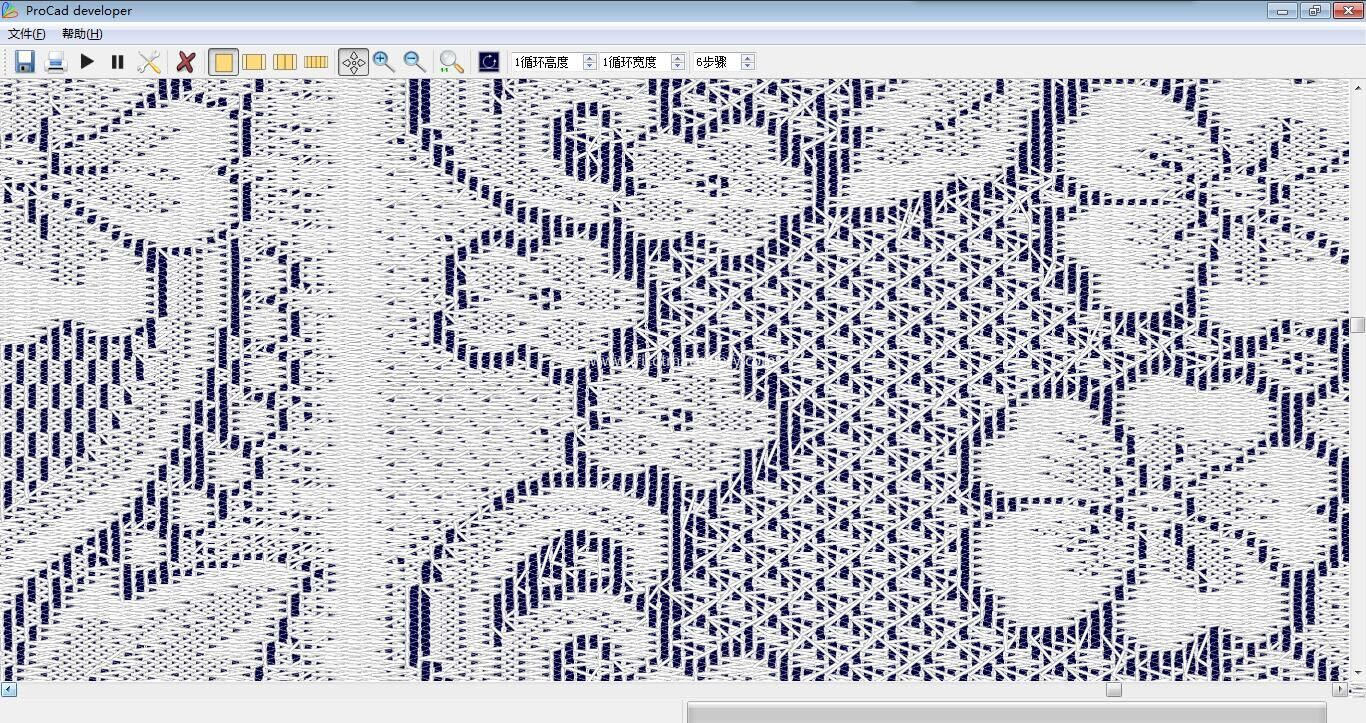

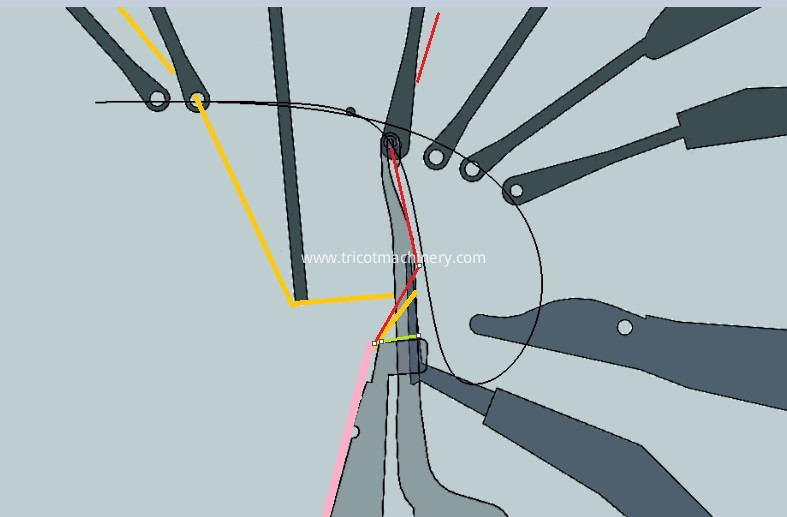

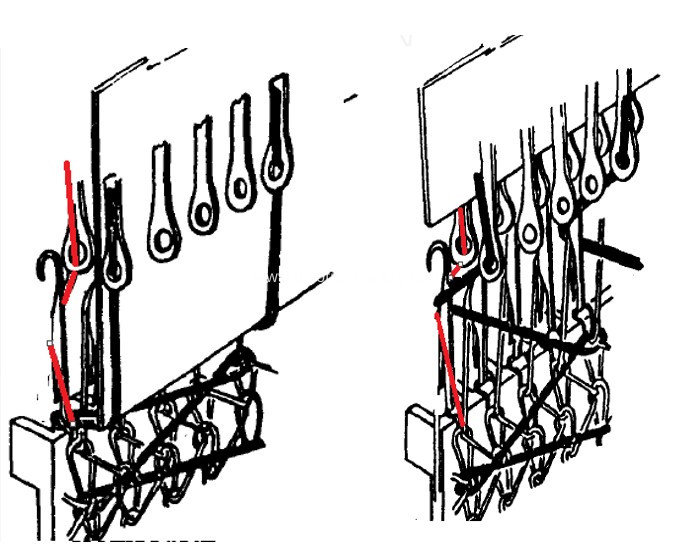

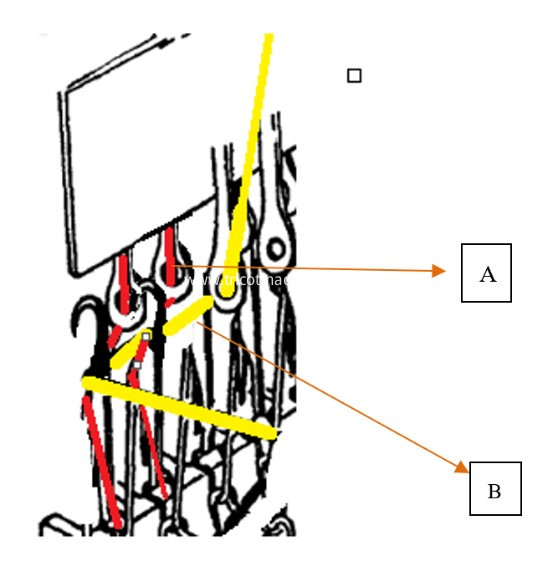

Besides, new advanced connecting link component applied on TH-4/1F and its improved models like TH-5/1F, and TH-7/1F. Because of which, the machine speed reaches to 600rpm under stable running condition. See image 2, the left is TH-4/1F structure, and the right is traditional structure.

Image 2

The left structure helps fall-plate movement more stable, and keeps same distant space to compound needle when it is in either before or back to compound needle. Because of which, the fall plate stitch is higher density instead of loose.

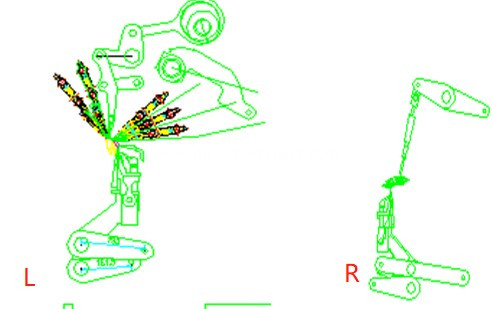

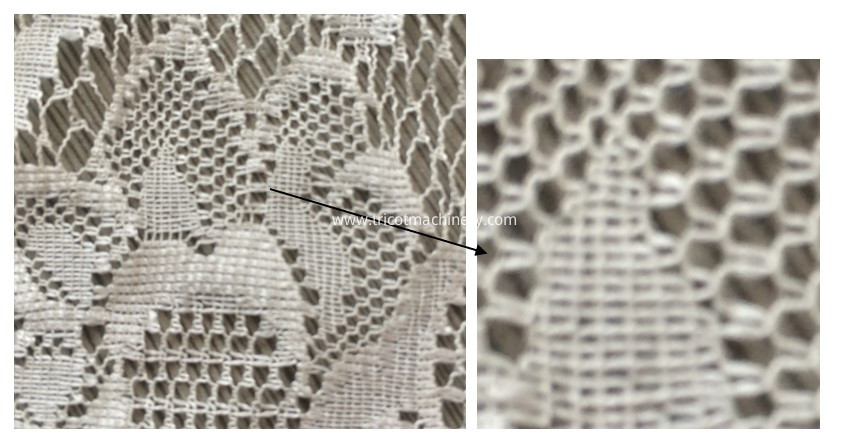

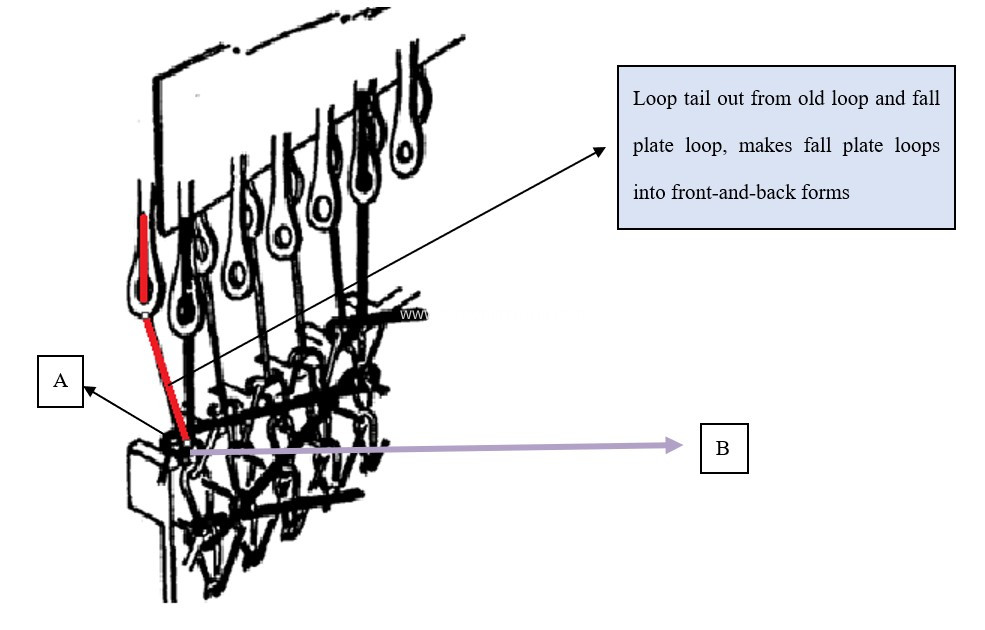

Image 3 indicates fall plate position to piezo jacquard needles.

Image 3

It shall be pointed that, because the fall plate position to needles keeps nearly same always, so fall plate and fall plate yarn touch surface become less, and it reduces the friction between them, in hence, it increases machine running speed as well as machine running life span.

Compared with traditional structure, our TH-4/1F raschel jacquard machine`s ground bars moves, and this subtle movement stitch GB2 bar in different position under overlap and underlap (see image 4, the black dot presents overlap and underlap yarn lap position),

Image 4

This structure saves space for fall plate and compound, what`s more, because of ground bars move, it leaves more time for fall plate when pressing yarn and making loops during overlap process, and the lower looping position makes ground bars work easier, and same direction fall plate effect is possible.

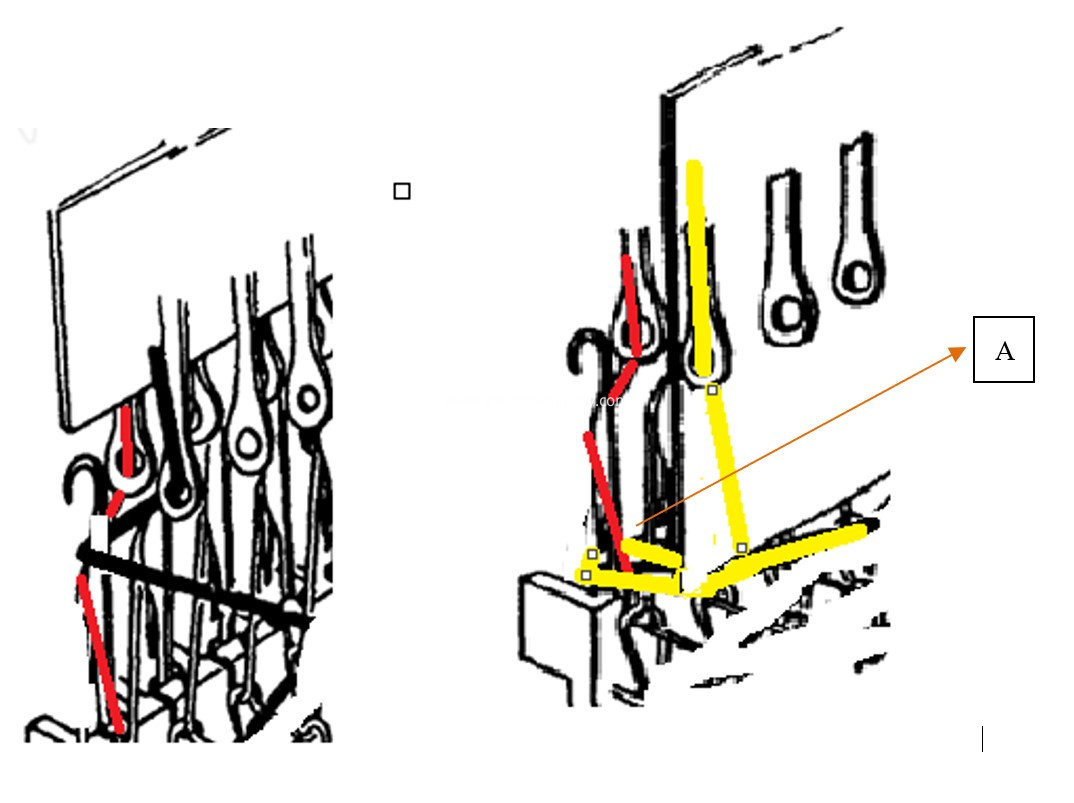

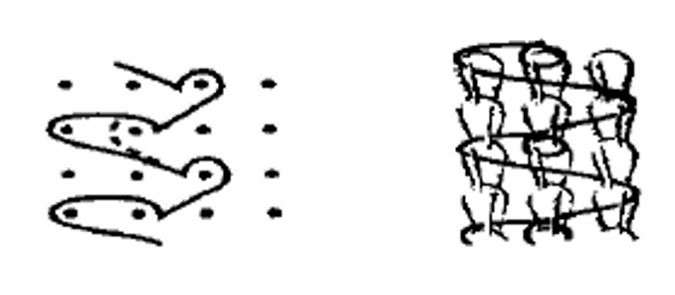

When same direction fall plate forms, the shogging process starts, so ground yarn barely touch fall plate yarn. Fall plate loops shall under tongue needles when overlapping (see image 5).

Image 5

It is obvious that the ground yarn (red color) and fall plate yarn (yellow color) are separate.

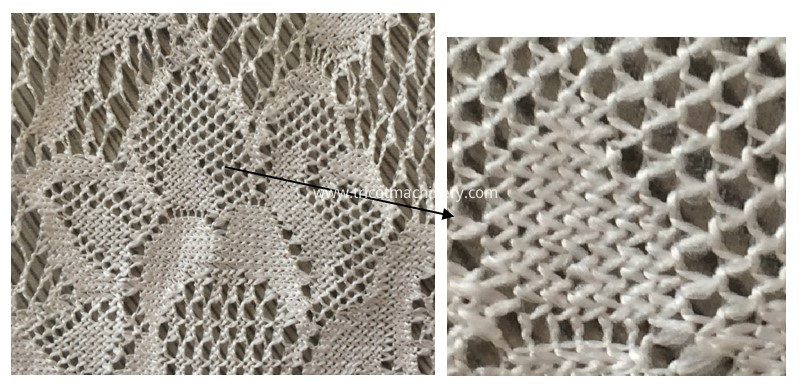

Same direction fall plate effect is another unique for TH-4/1F machine, the difference of same or reverse direction fall plate effect as follows:

Same direction in-lay effect.

Reverse In-lay Effect

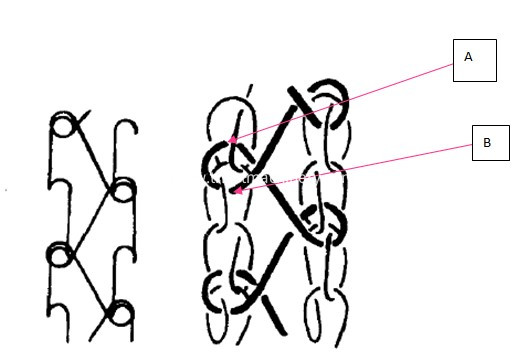

Reverse In-lay appear as [8" form, the loop tail makes 3D effect, while the whole pattern usually unclear and looks loose. The reason of which is that this effect is accomplished by both fall plate yarn and ground bar yarn (see image 6).

see image 6

Because of reverse looping, fall plate yarn and ground yarn are independent, jacquard yarn pressed by fall plate, and ground yarn gives no any interference and it places in position A. Because of ground yarn`s stop at jacquard yarn backside, jacquard yarn finds no block at position B, so the fall plate effect looks like [8" form (see image 7).

see image 7

Same Direction Fall Plate Effect

Above image shows that open stitch of jacquard yarn and ground yarn move same direction, ground yarn loop tail works on jacquard yarn. Because of the open stitch, position A receives no press force and so the jacquard yarn and in-lay yarn combined. This kind in-lay effect is different from ground bar in-lay alone, it is more suitable for loops across more than 3 needles.

Loops Effect:

Jacuqard loop at Position A,ground yarn aviods blcok jacquard back looks since it is open stitch

Two Needles Overlap

loop tail of A covers jacquard yarn B, when stitch process done, jacquard yarn turns to left.

Stitch Effect:

666666;background-color:#FFFFFF;"> · TH-4/1F Running Videos On-site

https://youtu.be/TCoax1bJFX4 (E24 Curtain Textile);

https://youtu.be/o9zPY1S8XEA (Hijab Textile);

https://youtu.be/4ri1XEiEpfg (E18 Curtain Textile);

Machine Details: Raschel Jacquard Warp Knitting Machine China Manufacturer (warpknittingmachinery.com).

A-ZEN services branches locate in Zhejiang (China), Fuzhou (China), Changzhou (China), Surat (India), Istanbul (Turkey) and Cairo (Egypt), we offer machine maintenance, technical training as well as textile development service for our customers.

Business Contact: info@azentex.com; edison@azentex.com