Company Details

Company Details

Warp Knitting Machine ( 34 )

Warp Knitting Machine ( 34 ) Warping Machine ( 6 )

Warping Machine ( 6 )666666;background-color:#FFFFFF;"> I. About RDJ4/2(EL) and RDJ6/2(EL)

Double Needle Bar Machine with Piezo-Jacquard technology is capable of joining separate fabric surfaces with various patterns. Its application includes outwear, seamless wear such as pantyhose and sportswear and shoes.

Machine Specification:

·working width: 90", 138";

·gauge: E16, E18, E24, E28;

·pattern drive: EL drive;

·knock-over comb bar distance: 1-10mm;

·knitting elements: two individual latch needle bars, two knock-over comb bars and two stitch comb bars;

·fabric take-up: electronic drive;

·batching device: electronic drive.

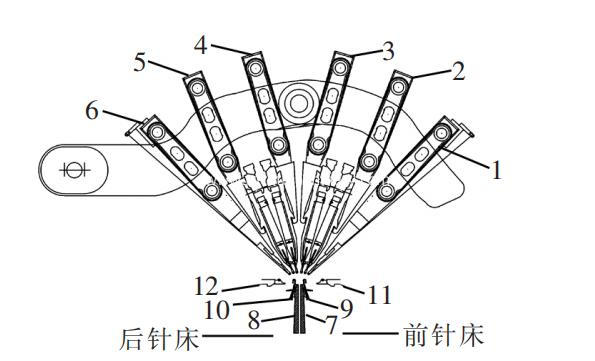

About Bars

Four (two) ground guide bars, two piezo-jacquard guide bars (spliy jacquard), which make stitch-forming on both needle bars.

"1": GB1; "2.3": JB2(JB2.1, JB2.2); "4.5": JB3 (JB3.1, JB3.2); "6":GB4; "7": Front knock-over comb bar;

"8": Back knock-over comb bar; "9.10": Latch Needle Beds; "11.12": Sinker Beds.

GB1 stitch-forming on front needle bed, GB4 stitch-forming on back needle bed; JB2 and JB3 can make stitch-forming on both beds. No.9 and No.10 is latch needle beds, use Groz-beckert 50.60G02 spec needle.

Yarn spec suggested to use above 15.6tex (140D), if knock-over distance is too narrower, the fabric is easily to accumulated so that they can not form new loops. While if the knock-over distance is too wider, machine would be difficult to run. We suggest the knock-over distance set between 1.2-1.5 mm.

II Basic Structure of Double Needle Jacquard Designs (RDJ4/2)

As we are clear that GB1 and GB4 make pillar stitch, and JB2 mostly form stitch on front bed and JB3 on back one. The notation of each bars are:

GB1: 1-0-1-1/0-1-1-1//;

JB2: 1-0-1-1/1-2-1-1//;

JB3: 1-1-1-2/1-1-1-0//;

GB4: 1-1-0-1/1-1-1-0//.

Shoes pattern mainly formed by JB2 and JB3 movements. Piezo needles not move on both odd and even courses, in which condition the light structure forms. When piezo needles move on odd courses, net structure forms, while when move on even courses, heavy structure forms.

Special Structure

When GB1 and JB2 form stitch only on front bed and JB3 and GB4 form stitch only on back bed, the separate net effect appear. As image 2b shows that, when net of front bed and net of back bed move at same needles position, the shoes textile will show empty holes, which could be used for shoelace holes.

And as image 2c tells that when JB3 forms stitch on front bed with colored or different spec yarn from JB2 and GB1`s, the two separate surface would be joined together to become a unit complete textile. Lastly, in image 2d, when JB2 forms stitches on both front and back beds, while JB3 only do on back bed, the separate surfaces also joined and front surface only show yarns from GB1 and JB2.

Example of Design

1. Calculate Size:

Before starting design, we shall learn how to change shoes` size into design courses.

T means total column of shoes, and V means total courses of shoes. W stands for size in horizontal side(cm), and H means size in vertical side(cm).

T=W*WPC;

V=H*CPC.

2. Software Color Matrix

In design software, [H" stands for Piezo non-movement, and [T" means Piezo movement.

There are many colors of design software which stands for different structure, here we give you a brief example:

4# and 8# stand for Light Structure, 1# means Heavy Structure, 12# represents Net Structure, 26# is symbol of Middle Structure between Light Structure. 25# and 18# mean Link Structure between Net Structure and Heavy Structure accordingly.

Yarn Spec.

GB1: 15.6 tex/48F (140D/48F) semi bright nylon FDY;

JB2: 23.3 tex/72F (210D/72F) semi bright nylon DTY;

JB3: 22.2 tex/96F (200D/96F) semi bright polyester DTY;

GB4: 16.7/48F (150D/48F) semi bright polyester DTY.

Machine Type & Technique Parameter:

RDJ4/2 E24 138"

CPC on machine: 16 c/cm;

Finished weight: 478.5g/m2;

Running Speed: 450 r/min;

Yarn Let-off:

·GB1: 1,700 mm/rack;

·JB2: 2,380 mm/rack;

·JB3: 2,500 mm/rack;

·GB4: 1,750 mm/rack;

Design Matrix

JB2 includes 1#, 4# and 12#, and JB3 includes 1#, 4#, 12#, 18#, 25# and 26#. JB3 forms stitch on both front and back beds. Because of this, GB4 and JB3 runs more yarn than GB1 and JB2 do.

Finished Sample:

III About Process

It is noted that setting and finishing are vital to shoes textile process, here we share one useful experience with you.

Firstly, we need to measure size of shoes carefully, and match with transparent cardboard (note that shoes fabric is 3 cm bigger than standard cardboard).

After pre-setting, fabric size is 0.5 cm bigger than standard cardboard. Next steps are dyeing and setting. To make sure the shoes size is general correct, the tolerance scope shall be within -2~2 mm.

You are welcome to share your opinion and comments with us, shared knowledge will extend our passion to warp knitting technology.

Product Link: https://www.azentex.com/product/143.html